Step-by-Step Guide to Preventing Weld Undercut in Different Metals

Step-by-Step Guide to Preventing Weld Undercut in Different Metals

Blog Article

Comprehending the Causes and Solutions for Undercut Welding in Steel Fabrication Processes

In the world of steel construction procedures, the incident of undercut welding postures a considerable difficulty that demands a detailed understanding of its reasons and feasible solutions. The intricate interplay of various aspects throughout welding operations can result in this unfavorable phenomenon, impacting the structural honesty and general high quality of the bonded joints - Preventing weld undercut. By exploring the source of undercut welding and checking out reliable remedial actions, makers can raise the standard of their handiwork and guarantee the production of perfect steel parts

Usual Root Causes Of Undercut Welding

Often forgotten in steel fabrication, undercut welding occurs due to various elements that require careful focus and expertise to be effectively reduced. In addition, inappropriate welding strategies, such as utilizing the incorrect welding angle or take a trip rate, can also add to damage development. The selection of welding parameters, such as voltage, current, and cable feed speed, plays a considerable function in the incident of undercut welding.

Effect of Incorrect Welding Parameters

Incorrect welding criteria can significantly jeopardize the stability and top quality of welded joints in metal fabrication procedures. The effect of wrong welding parameters materializes in different methods, leading to architectural weak points and defects in the bonded components. Careful focus to welding parameters is critical to make sure the manufacturing of high-quality welds with the desired mechanical residential properties and architectural honesty.

Impact of Improper Torch Angle

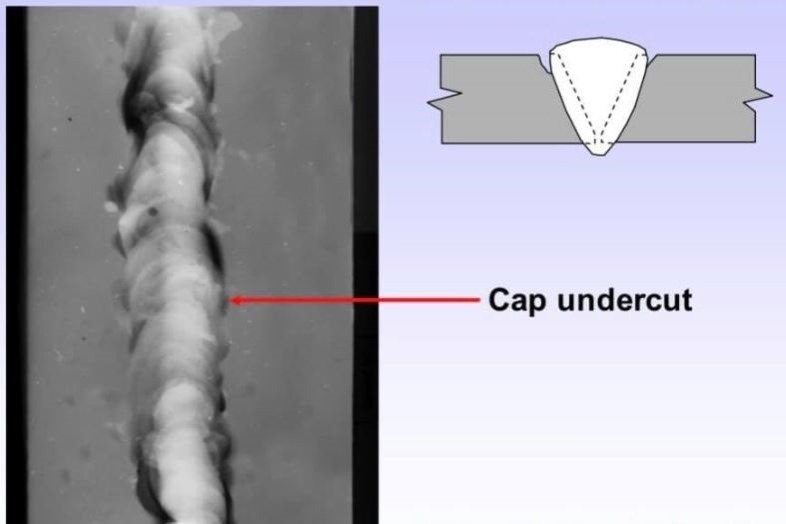

Improper lantern angle in welding procedures can substantially affect the quality and integrity of the last weld joints in steel construction processes. Damaging is an usual welding flaw where a groove forms along the weld toe, weakening the joint and endangering its architectural integrity.

A lantern angle that is as well steep can lead to not enough infiltration, incomplete fusion, and raised spatter. On the various other hand, a torch angle that is too superficial can lead to extreme infiltration, burn-through, and distortion of the base product. Preventing weld undercut. Appropriate lantern angle is crucial for making sure consistent weld quality, toughness, and appearance

To avoid damaging and other defects brought on by improper lantern angles, welders need to be trained to preserve the correct lantern angle throughout the welding process. Normal tracking and change of torch angles throughout welding can assist achieve audio welds with minimal flaws.

Role of Inadequate Welding Strategies

One more aspect of inadequate welding techniques is improper weld preparation. Poor cleaning of the base steels, wrong joint style, or inadequate edge preparation can all add to damage welding. In addition, poor protecting gas protection or utilizing the wrong kind of click to read more gas can cause incomplete fusion and the development of undercut issues.

To resolve the function of inadequate welding techniques in steel construction procedures, it is vital to supply detailed training for welders. Proper education and learning on welding specifications, joint preparation, and securing gas selection can aid stop undercut welding and ensure high-quality welds in steel fabrication tasks.

Effective Solutions for Undercut Welding

Addressing undercut welding in metal fabrication needs implementing efficient solutions to boost weld quality and architectural integrity. Among the primary options to combat undercut is to change welding parameters such as voltage, present, and take a trip speed to make sure proper warm input and blend. By fine-tuning these settings, welders can stop excessive melting of the base metal and filler product, reducing the probability of undercut development.

Additionally, appropriate joint prep work is essential in preventing undercut. Making sure tidy base steel surfaces complimentary of impurities and using the proper bevel angle can aid advertise better weld i loved this penetration and minimize the threat of undercut - Preventing weld undercut. Employing appropriate welding methods, such as weaving or oscillating the lantern, can also help in dispersing warmth equally and filling the weld joint properly, lessening the opportunity of undercut issues

Furthermore, selecting the appropriate welding consumables, including electrodes and filler metals, is necessary in minimizing undercut. Making use of products with appropriate chemical compositions and mechanical Full Report homes can add to accomplishing audio welds with very little undercut. Routine assessment and quality assurance procedures need to additionally be applied to identify and resolve undercut concerns without delay, making certain the total honesty of produced metal elements.

Conclusion

In conclusion, understanding the reasons and options for undercut welding in metal fabrication processes is crucial for attaining high-grade welds. By resolving typical causes such as incorrect welding criteria, incorrect torch angle, and inadequate welding strategies, welders can stop undercutting and ensure solid, resilient welds. It is necessary to focus on these aspects and carry out effective remedies to enhance the overall welding procedure and end product high quality.

Report this page